Contents

- 1 The Role of ISO 9001 in Quality Management System (QMS)

- 1.1 Case Study: Toyota’s Economic Advantage through ISO 9001 Implementation

- 1.2 Conclusion

- 1.3 The Role of Environmental Standards in Product Life Cycle and Supply Chains

- 1.4 Case Study: Unilever’s Economic Advantage Through ISO 14001 Implementation

- 1.5 Conclusion

- 1.6 The Role of Statistical Quality Control (SQC) and Statistical Process Control (SPC) in Quality Assurance and Product Reliability

- 1.7 Understanding Statistical Quality Control (SQC)

- 1.8 Role of Statistical Process Control (SPC) in Product Reliability

- 1.9 Conclusion

- 1.10 The Role of Design for Manufacture (DFM) and Design for Assembly (DFA) in Enhancing Product Quality and Reliability

- 1.11 Case Study: Apple’s Use of DFM/DFA in MacBook Design

- 1.12 Conclusion

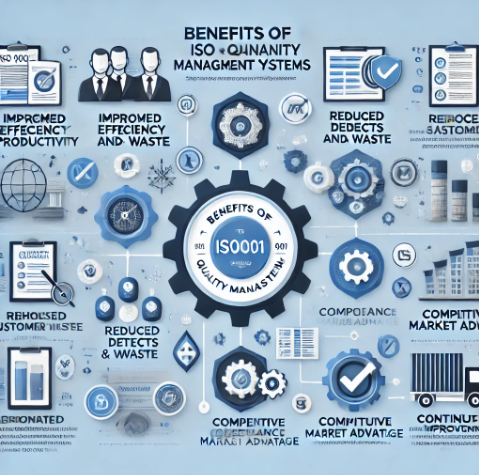

The Role of ISO 9001 in Quality Management System (QMS)

ISO 9001 is a globally recognized standard for Quality Management Systems (QMS), developed by the International Organization for Standardization (ISO). It provides a structured framework to ensure consistent quality in products and services while improving operational efficiency. The standard emphasizes customer satisfaction, continuous improvement, and adherence to regulatory requirements. By implementing ISO 9001, organizations establish standardized processes, risk management protocols, and quality controls that enhance overall performance.

One of the core principles of ISO 9001 is a process-based approach, ensuring that every aspect of production or service delivery is systematically managed. This leads to improved efficiency, reduced waste, and better resource utilization. The standard also requires top management commitment, fostering a culture of quality throughout the organization. Compliance with ISO 9001 enhances credibility and provides a competitive advantage in the marketplace, as customers and stakeholders trust businesses that adhere to internationally recognized quality standards.

Furthermore, ISO 9001 certification improves supply chain management by ensuring standardized quality requirements across vendors and suppliers. Organizations also benefit from data-driven decision-making through regular audits, performance evaluations, and continuous process refinement. This structured approach not only improves customer satisfaction but also boosts profitability by minimizing defects, reducing operational costs, and enhancing market reputation.

Case Study: Toyota’s Economic Advantage through ISO 9001 Implementation

Toyota, a global leader in the automotive industry, has successfully leveraged ISO 9001 to maintain high standards of quality and efficiency. The company implemented ISO 9001 as part of its broader Total Quality Management (TQM) strategy, integrating structured processes to enhance productivity and reduce costs.

Before adopting ISO 9001, Toyota faced challenges related to inconsistent quality in its global supply chain. Variations in production processes across different facilities led to inefficiencies, increased defect rates, and higher operational costs. By aligning its quality management systems with ISO 9001, Toyota standardized procedures across all production units, ensuring uniform quality and compliance with international regulatory requirements.

The economic advantages of ISO 9001 implementation were evident in multiple ways. Firstly, Toyota achieved a significant reduction in production defects, leading to lower warranty claims and improved customer satisfaction. The company’s ability to maintain consistent quality across different markets strengthened its global brand reputation, driving higher sales and market share. Additionally, the improved efficiency of supply chain management reduced production costs by minimizing waste and optimizing resource utilization.

ISO 9001 also facilitated continuous improvement through structured feedback mechanisms. Toyota’s commitment to ongoing process enhancement enabled the company to innovate rapidly, keeping pace with evolving customer expectations and technological advancements. As a result, Toyota not only maintained high profitability but also reinforced its position as an industry leader in quality and reliability.

Conclusion

In conclusion, ISO 9001 plays a crucial role in ensuring systematic quality management, operational efficiency, and customer satisfaction. Organizations like Toyota have demonstrated that ISO certification leads to tangible economic benefits by reducing costs, enhancing reputation, and driving business growth. Implementing ISO 9001 is not just a compliance requirement but a strategic tool for long-term success.

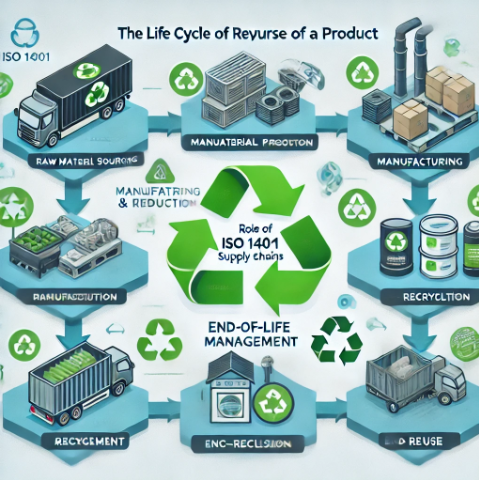

The Role of Environmental Standards in Product Life Cycle and Supply Chains

Environmental standards, particularly ISO 14000 and ISO 14001, play a crucial role in ensuring sustainable business practices across the entire life cycle of products. These standards focus on minimizing environmental impact, reducing waste, and promoting resource efficiency while maintaining economic growth (Brammer, Hoejmose & Millington, 2011). The life cycle of a product includes raw material extraction, manufacturing, distribution, usage, and end-of-life disposal or recycling. Environmental standards ensure that organizations adopt sustainable practices at every stage (Delmas & Toffel, 2008).

ISO 14001, a key part of the ISO 14000 family, provides a framework for businesses to develop an Environmental Management System (EMS). This system helps organizations comply with environmental regulations, improve efficiency, and reduce pollution. In the forward supply chain, which includes raw material sourcing, production, and distribution, ISO 14001 ensures sustainable procurement, energy-efficient manufacturing, and reduced emissions during transportation (Epstein & Buhovac, 2014). Companies that adhere to these standards can significantly lower operational costs by optimizing resource consumption and improving waste management strategies.

On the other hand, the reverse supply chain, which deals with product returns, recycling, and disposal, also benefits from ISO 14001. The standard encourages organizations to design products for easier recycling and reuse, reducing landfill waste and promoting a circular economy (Goyal, Rahman & Kazmi, 2013). Businesses implementing closed-loop supply chains benefit from cost savings by reclaiming valuable materials from end-of-life products. Compliance with environmental standards enhances corporate reputation, attracts eco-conscious consumers, and ensures long-term sustainability.

Case Study: Unilever’s Economic Advantage Through ISO 14001 Implementation

Unilever, a global consumer goods company, has successfully leveraged ISO 14001 to enhance sustainability while achieving economic gains. Before implementing the standard, Unilever faced challenges related to high energy consumption, excessive waste generation, and regulatory compliance issues (ISO, 2015). By adopting ISO 14001, the company integrated an Environmental Management System (EMS) into its operations, leading to significant improvements in resource efficiency and waste reduction (Nishitani, 2010).

One of the key initiatives under ISO 14001 was the reduction of carbon emissions across its manufacturing and supply chain processes. Unilever optimized energy use in its production facilities by investing in renewable energy sources and energy-efficient technologies. The company also restructured its logistics and transportation strategies, reducing fuel consumption and emissions (Seuring & Müller, 2008). These changes resulted in substantial cost savings on energy bills and minimized regulatory risks.

In the reverse supply chain, Unilever implemented sustainable packaging solutions by increasing the recyclability of its product packaging. The company also promoted waste recovery programs, allowing consumers to return used products for responsible recycling (Zeng et al., 2005). These efforts not only reduced environmental impact but also enhanced Unilever’s brand image as an environmentally responsible organization, attracting more eco-conscious consumers and increasing market share (Boiral, 2011).

The economic advantages of ISO 14001 implementation were evident in Unilever’s financial performance. The company reported significant cost savings from waste reduction, lower raw material expenses, and optimized production processes. Additionally, adherence to ISO 14001 enabled Unilever to secure partnerships with environmentally responsible suppliers and retailers, further strengthening its market position (Bansal & Hunter, 2003).

Conclusion

Environmental standards like ISO 14000 and ISO 14001 are essential for sustainable business practices across the forward and reverse supply chains. By implementing these standards, organizations can achieve cost savings, regulatory compliance, and enhanced corporate reputation. The case of Unilever demonstrates how adopting ISO 14001 can lead to economic benefits while promoting environmental sustainability. Businesses that integrate environmental standards into their operations not only contribute to a greener planet but also gain a competitive advantage in the global market.

The Role of Statistical Quality Control (SQC) and Statistical Process Control (SPC) in Quality Assurance and Product Reliability

In the modern manufacturing and service industries, ensuring product quality and reliability is critical to maintaining customer satisfaction and operational efficiency. Statistical Quality Control (SQC) and Statistical Process Control (SPC) play a crucial role in quality assurance by identifying defects, monitoring process performance, and minimizing variations in production. These statistical methodologies allow organizations to maintain consistency in their products, reduce waste, and improve productivity. The National University of Singapore (NUS), known for its strong engineering and business programs, integrates these quality control methodologies into its research and academic curriculum, supporting industries in implementing best practices for quality management (Ashby and Jones 2012).

Understanding Statistical Quality Control (SQC)

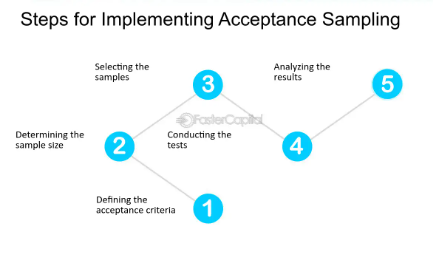

SQC refers to the application of statistical methods to monitor, control, and improve product quality throughout the production process. It ensures that manufactured goods meet the required specifications and perform reliably over time. SQC consists of three major categories:

- Descriptive Statistics – This includes measures like mean, standard deviation, and range, which summarize data and help in understanding process performance.

- Acceptance Sampling – A statistical method used to inspect a sample of products from a batch to determine whether the entire batch meets quality standards.

- Statistical Process Control (SPC) – A method used to monitor and control a process using statistical techniques, ensuring that production remains within defined limits.

The diagram below illustrates the Acceptance Sampling Process, commonly used for quality control in consumer products such as mobile phones and household appliances.

Figure: Acceptance Sampling Flowchart – showing lot selection, sample inspection, decision-making process for acceptance or rejection

At NUS, research on quality control methodologies focuses on optimizing production systems using advanced statistical tools. In collaboration with industries, NUS applies SQC techniques to ensure robust quality frameworks in sectors like electronics, pharmaceuticals, and food production (Oakland, 2014).

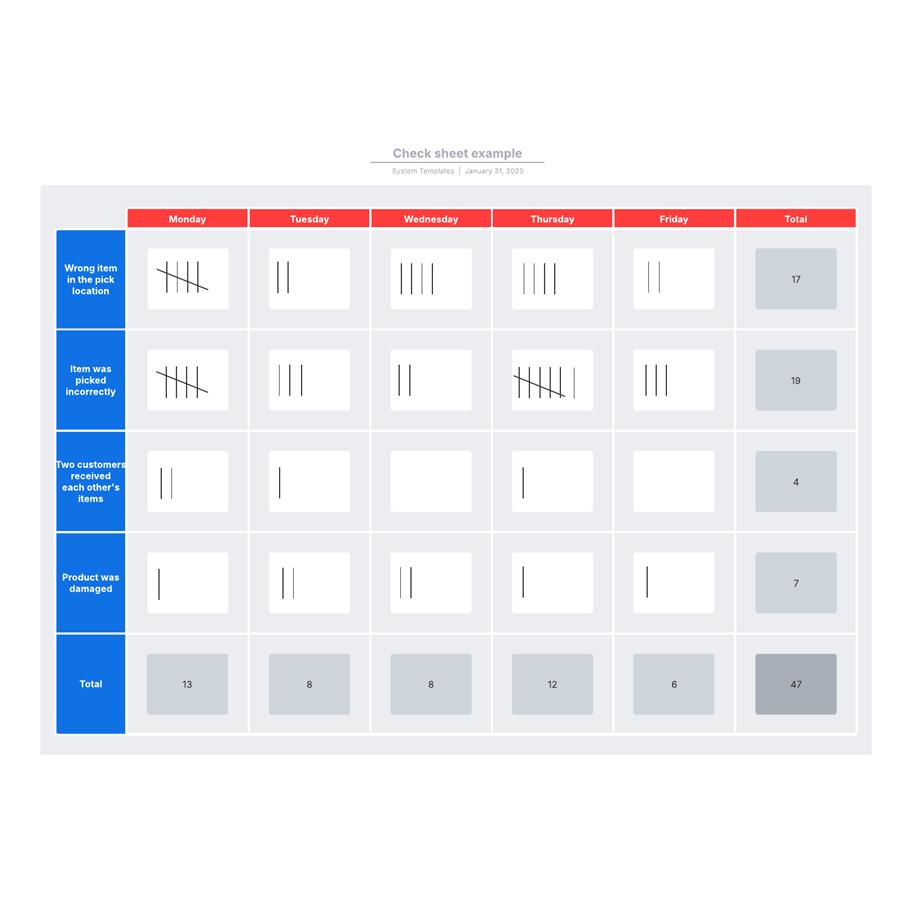

Fig: Check sheet sample

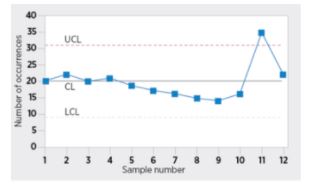

Fig: Sample SPC Chart

Fig: Histogram

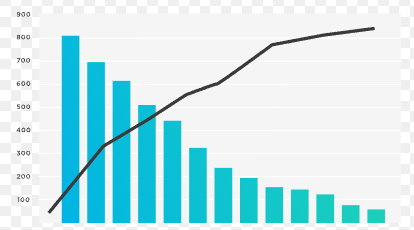

Fig: Pareto chart

Role of Statistical Process Control (SPC) in Product Reliability

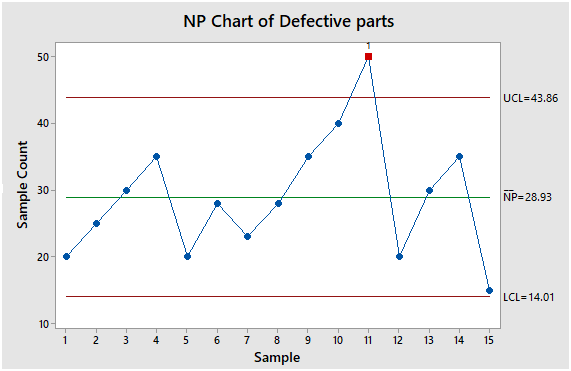

SPC is a subset of SQC that focuses on real-time monitoring of production processes to detect deviations before defects occur. It employs control charts and other statistical tools to assess process stability and reduce variability. By continuously analysing data, SPC enables organizations to take preventive actions rather than reactive ones.

One of the most widely used SPC tools is the Control Chart, which helps manufacturers track variations in product dimensions, weight, or other critical attributes.

Figure: Control Chart Example – illustrating upper and lower control limits for monitoring defects in consumer electronics

For instance, in semiconductor manufacturing, a field where NUS conducts extensive research, SPC ensures that microchips meet precision standards. By implementing control charts, companies can detect abnormalities in wafer thickness, ensuring that defective chips do not reach the market (Wheeler and Chambers, 1992).

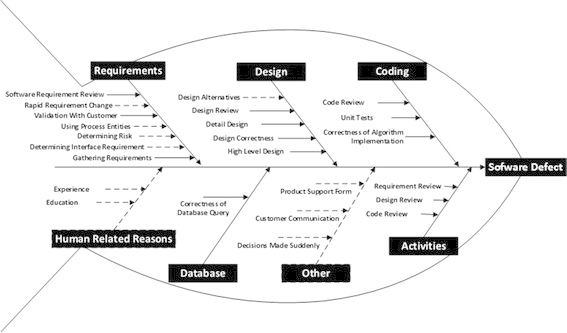

Another essential SPC tool is the Pareto Chart, which helps identify the most common defects affecting product quality. The Fishbone Diagram (Ishikawa Diagram) is also frequently used to determine root causes of defects in production.

Figure: Fishbone Diagram for Identifying Root Causes of Product Defects

By integrating SPC tools into production processes, industries can reduce defects, improve efficiency, and enhance customer satisfaction. NUS, through its engineering and management programs, provide students and researchers with hands-on experience in implementing these quality control techniques, preparing them to contribute effectively to various industries (Montgomery, 2020).

Conclusion

SQC and SPC are fundamental to achieving high-quality, reliable products. By employing techniques such as acceptance sampling, control charts, and root cause analysis, industries can enhance production efficiency and reduce defects. The National University of Singapore plays a vital role in advancing research and education in these methodologies, collaborating with industry partners to improve quality standards across various sectors (Mitra, 2016). Through the integration of statistical quality control tools, companies can ensure product reliability, minimize costs, and maintain competitive advantages in the global market.

The Role of Design for Manufacture (DFM) and Design for Assembly (DFA) in Enhancing Product Quality and Reliability

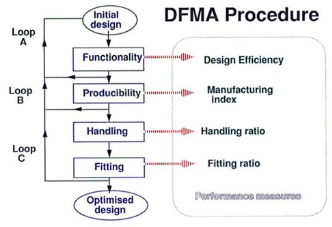

In modern engineering and manufacturing, Design for Manufacture (DFM) and Design for Assembly (DFA) are two essential methodologies that enhance product quality, reliability, and overall efficiency. These approaches focus on designing products in a way that simplifies manufacturing and assembly processes, reduces production costs, and minimizes defects. DFM primarily ensures that components are designed for ease of manufacturing with minimal waste, while DFA streamlines the assembly process by reducing the number of parts, improving fit, and minimizing assembly time. Together, these methodologies contribute to higher-quality, more reliable products that meet customer expectations (Ulrich and Eppinger 2015).

DFM involves considering manufacturing constraints and capabilities at the early design stage to prevent complex and costly production issues. It emphasizes material selection, process optimization, and component standardization to enhance manufacturability. By using DFM principles, companies can reduce material waste, improve production efficiency, and lower the likelihood of defects. For example, selecting a material that is easy to mould or machine ensures consistent product quality while reducing processing time. DFM also promotes the use of modular designs, which allow for easier upgrades and maintenance, enhancing long-term product reliability.

DFA, on the other hand, focuses on simplifying product assembly by minimizing the number of components, using standardized fasteners, and ensuring intuitive part orientation. A well-designed product under DFA principles reduces assembly errors, improves efficiency, and lowers labour costs. For example, by integrating multiple components into a single moulded part, companies can eliminate unnecessary screws and adhesives, reducing the risk of mechanical failures. Additionally, incorporating snap-fit joints instead of traditional fastening methods speeds up assembly and enhances structural integrity (Ashby and Jones 2012).

Case Study: Apple’s Use of DFM/DFA in MacBook Design

Figure: Design for manufacture

A notable example of successful DFM and DFA implementation is seen in Apple’s MacBook design. Apple is known for its high-quality, durable products, and its design process heavily incorporate DFM and DFA principles to enhance manufacturing efficiency and product performance.

During the design of the MacBook’s unibody chassis, Apple leveraged DFM to simplify manufacturing by using a single-piece aluminium frame, reducing the number of components required. Traditional laptop designs use multiple parts assembled with screws and adhesives, increasing manufacturing complexity and potential points of failure. By contrast, Apple’s unibody structure not only improves durability but also enhances aesthetics and thermal performance by allowing better heat dissipation.

DFA principles were also applied to reduce the complexity of assembly. For instance, Apple minimized the number of internal screws and used custom fasteners that allow for precise alignment during assembly. The MacBook’s keyboard and trackpad integration were optimized to reduce assembly steps, enhancing consistency and reducing defects. Additionally, the battery was designed to fit seamlessly into the chassis without excessive adhesives or brackets, making it easier to install while ensuring long-term reliability.

As a result, the MacBook’s manufacturing time was reduced, production efficiency improved, and product durability was significantly enhanced. The application of DFM and DFA not only improved Apple’s production process but also contributed to the premium quality and reliability that customers associate with its products.

Conclusion

DFM and DFA methodologies are crucial for improving product quality, reliability, and cost-effectiveness. By designing products with manufacturing and assembly in mind, companies can streamline production, reduce defects, and enhance durability. Apple’s MacBook design demonstrates how these principles lead to more efficient production, improved product performance, and long-term customer satisfaction. As industries continue to prioritize quality and efficiency, integrating DFM and DFA into the design process remains essential for achieving sustainable and high-performance product development.

Best Operations Management Expert

Best Operations Management Expert